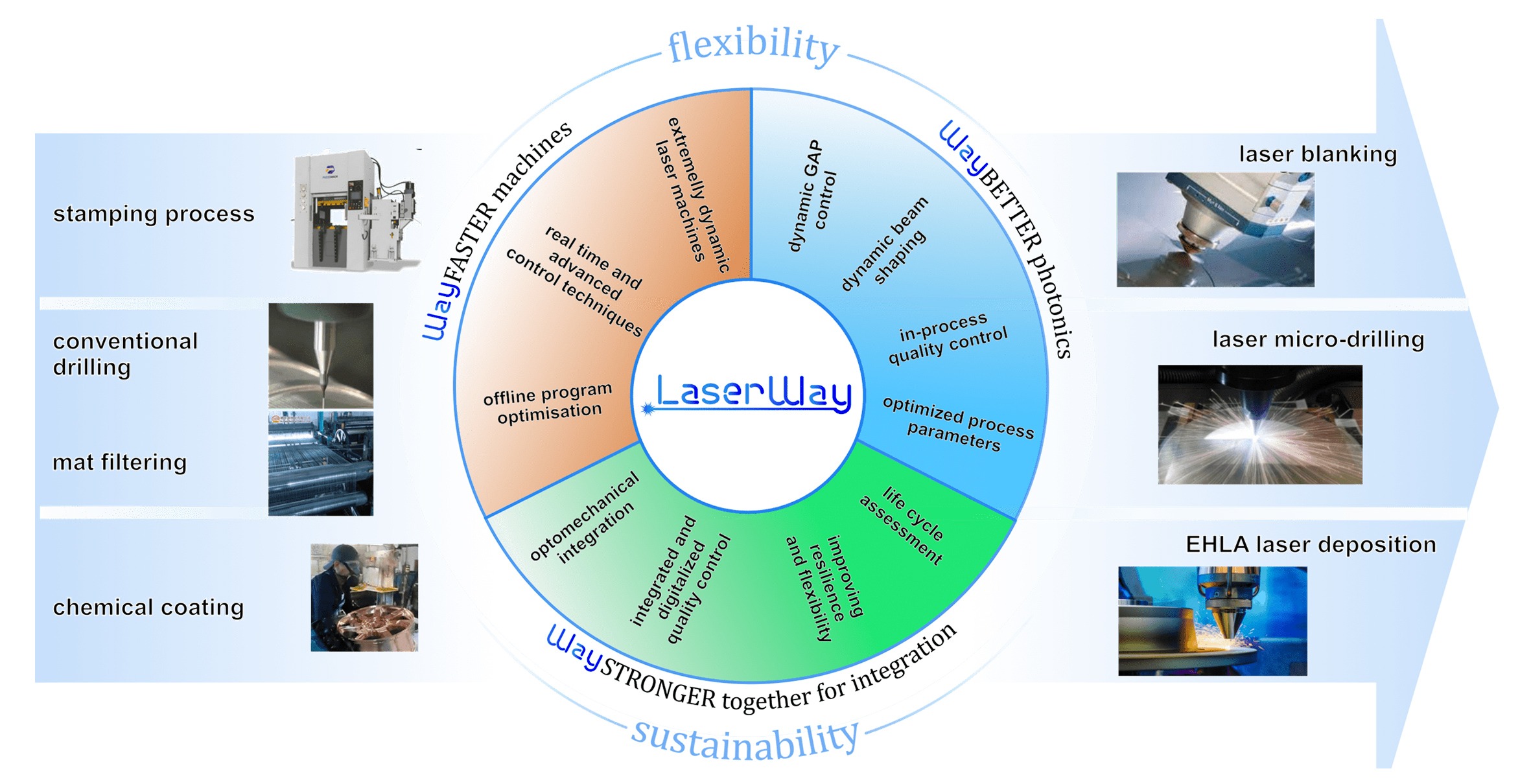

Approach

LaserWay will develop laser technologies within three modules. These advancements will support the creation of a machine and process capable of operating at extremely high speeds while precisely delivering photons at the right place and at the right time. By achieving its goals LaserWay seeks to facilitate flexible and sustainable production practices and ultimately replace conventional industrial applications.

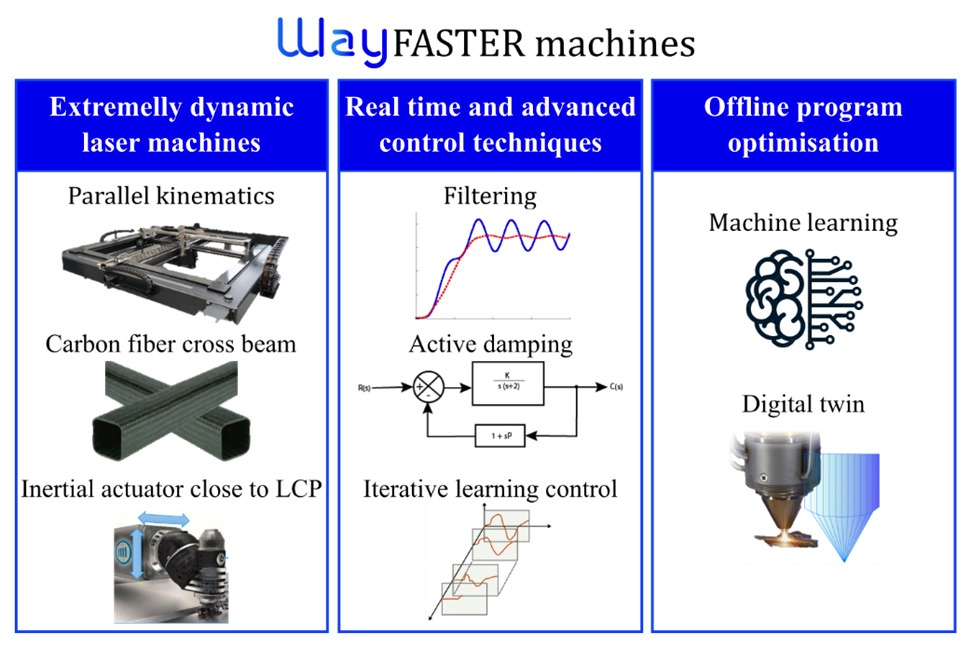

MODULE 1: WayFASTER

The aim of Module 1 is to improve the performance of laser manufacturing technologies through the development of lightweight machine designs, advanced vibration control techniques, and software optimizations specifically tailored for high-speed laser applications.

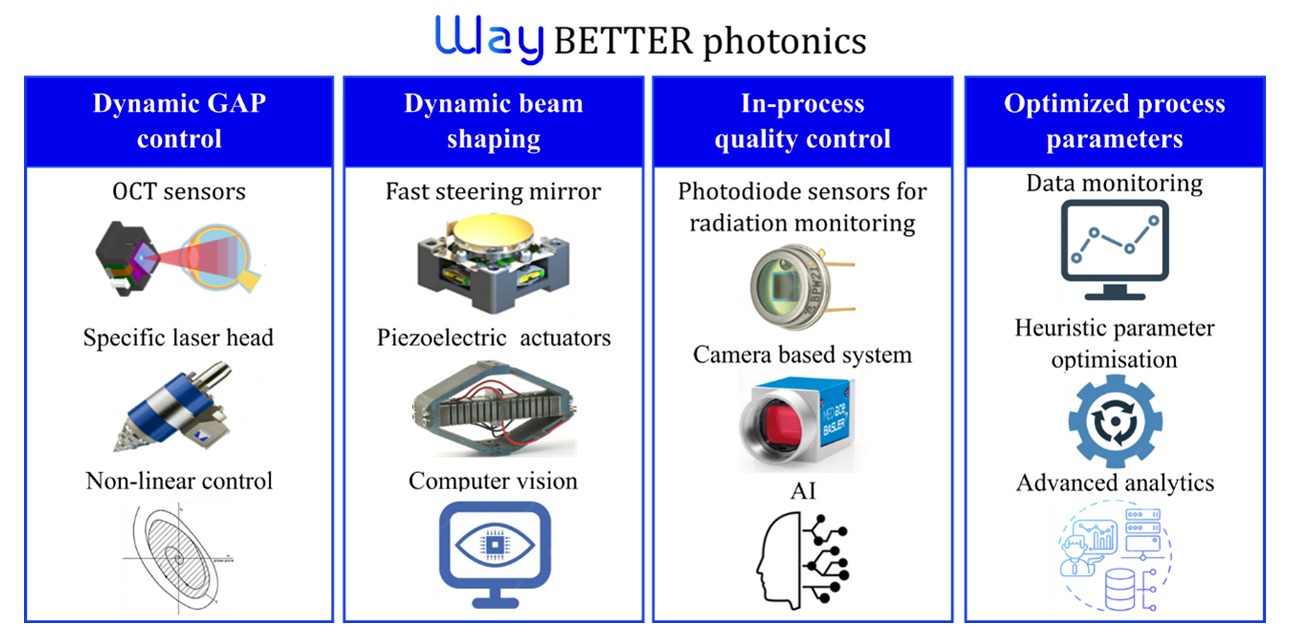

MODULE 2: WayBETTER

The aim of Module 2 is to improve the robustness and quality of the processes through (i) a highly dynamic gap control, (ii) a dynamic beam shaping mechanism, (iii) an in-process photonics quality control, and (iv) optimized process parameters for ultra-high-speed applications.

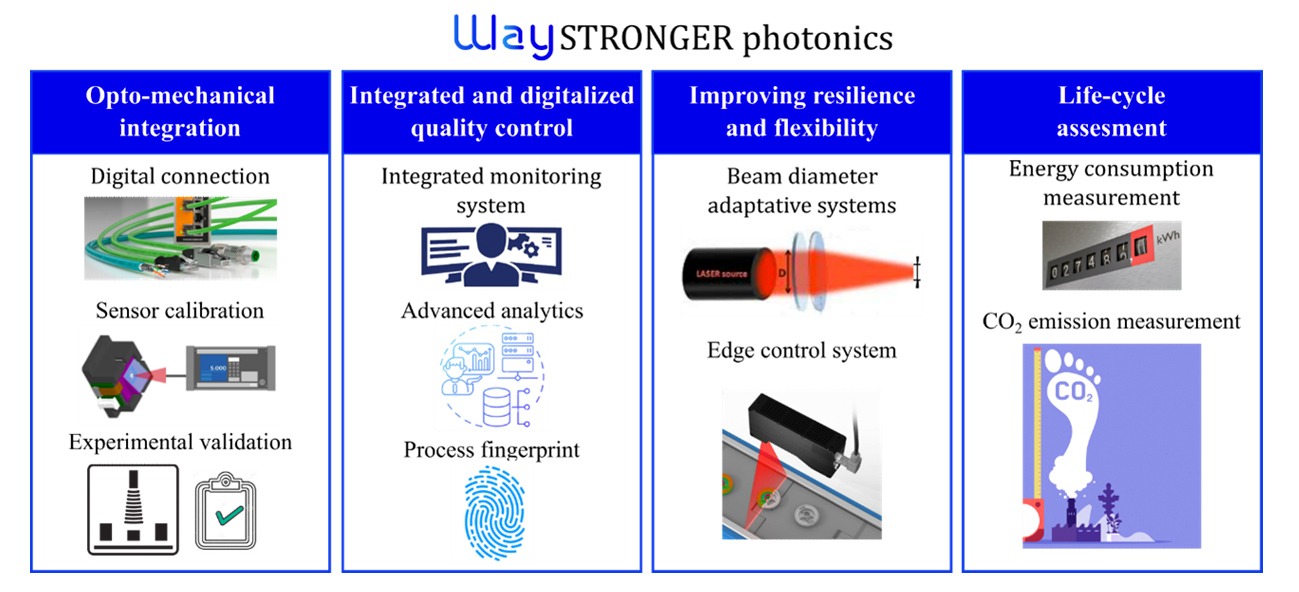

MODULE 3: WaySTRONGER

Module 3 activity area is dedicated to mechanically and digitally integrating the new technologies developed in Module 1 & 2 to enhance the sustainability, resilience, and flexibility of current manufacturing processes.

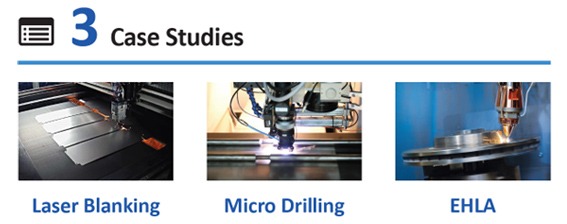

- Laser micro-drilling for aerospace and water filtering use case

- Laser blanking on moving coil for automotive use case

- Extremely High-speed LAser Material Deposition (EHLA) for aerospace use case

- Photonics and process control

- Dynamics and machine control

- Programming and optimization

engineering and technology – mechanical engineering – manufacturing engineering – medical and health sciences – health sciences – public health – epidemiology – pandemics – natural sciences – physical sciences – optics – laser physics