Cedric Hauschopp

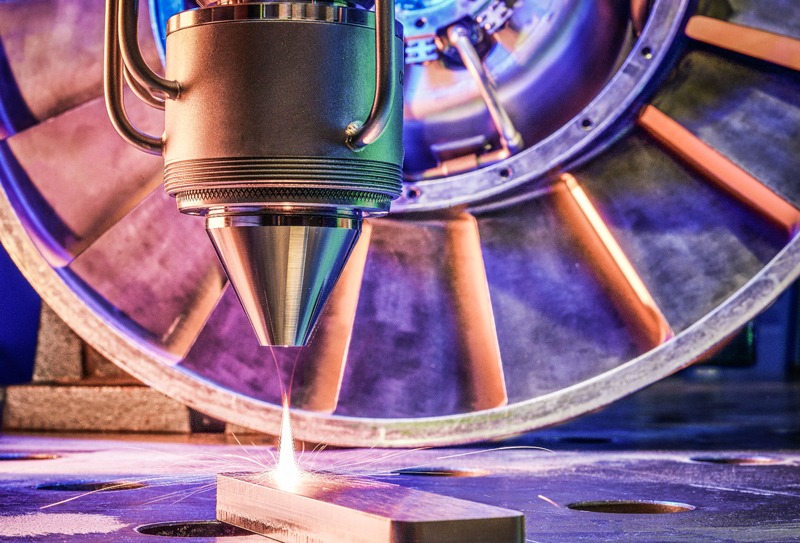

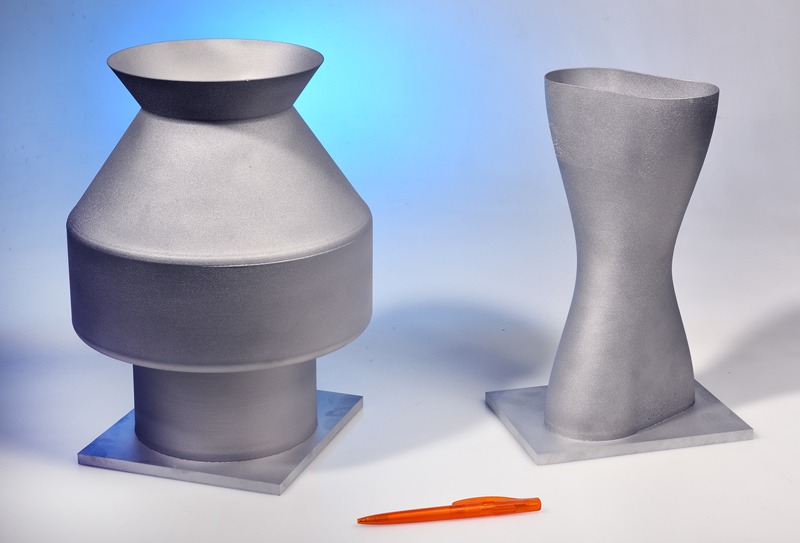

Fraunhofer ILT – for more than 35 years this abbreviation has stood for bundled know-how in the field of laser technology. Innovative solutions for manufacturing and production tasks, development of new technical components, competent consultation and education, highly specialized personnel, state-of-the-art technology and international references. The numerous customers of the Fraunhofer Institute for Laser Technology ILT come from industries such as automotive and mechanical engineering, chemistry and electrical engineering, aircraft construction, precision mechanics, medical technology and optics. With over 480 employees, more than 19,500 m² of net floor space and more than 40 spin-offs, Fraunhofer ILT is one of the most important contract research and development institutes in its field worldwide. Under one roof, the Fraunhofer Institute for Laser Technology ILT offers research and development, system design and quality assurance, consultation, and education. Numerous industrial laser systems from various manufacturers as well as an extensive infrastructure are available for research and development work. In the adjacent Digital Photonic Production DPP research campus, companies cooperating with Fraunhofer ILT work in their own laboratories and offices. The basis for this special form of technology transfer is a long-term cooperation agreement with the institute in the area of research and development. Benefits include the use of the technical infrastructure and the exchange of information with local experts. In addition to established laser manufacturers and innovative laser users, start-ups from the fields of special plant engineering, laser manufacturing technology, and laser measurement technology find a suitable environment here for the industrial implementation of their ideas. ILT will lead WP4 and will develop a process monitoring system optimized for high-speed laser processes and investigate the range of achievable feed rates and accelerations for laser metal deposition processes like EHLA. In WP5, ILT will share the recorded process data for defect detection and jointly analyze it for automated quality monitoring, while also working on ways to increase efficiency in laser cladding processes, such as powder reuse. LaserWay

Fraunhofer ILT

Corporate presentation

Role in the Project

Contact