Dr. Chen Hong

Chen.hong@acunity.de

0049-1737100968

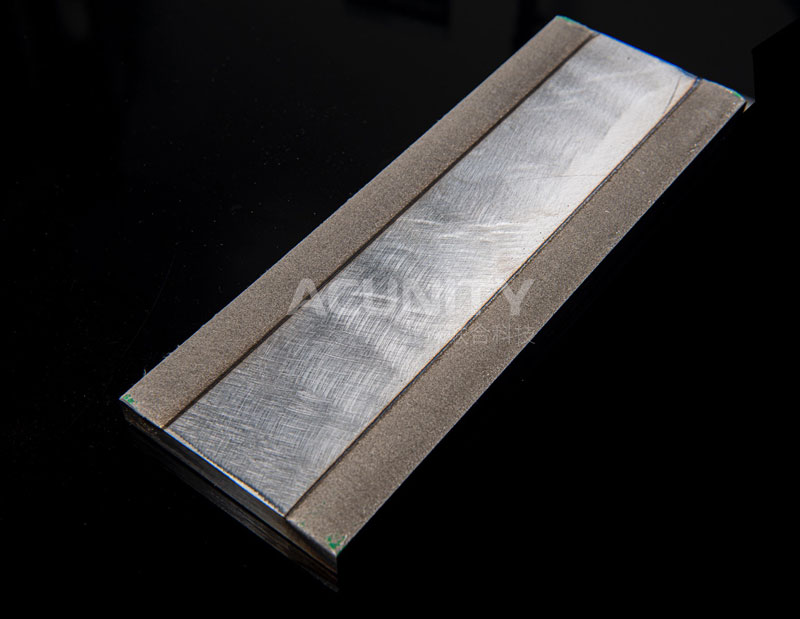

ACunity GmbH stands as a pioneering high-tech incubator aligned with the Fraunhofer Institute for Laser Technology ILT in Aachen, dedicating itself to advancing the forefront of laser technology applications in manufacturing. Positioned at the heart of the Photonics Cluster within the Fraunhofer ILT premises, ACunity GmbH leverages an unparalleled network of esteemed experts in laser technology, fostering innovation and excellence in its field. Over the past eight years, ACunity GmbH has been committed to developing core equipment for Extreme High-Speed Laser Metal Deposition (EHLA) as a cutting-edge alternative to traditional electroplating processes. The company has established two production bases focused on providing EHLA services for key components in the coal machinery and oil industries. To date, ACunity GmbH boasts an impressive annual production capacity exceeding 15,000 square meters. In 2019, the company achieved a significant breakthrough by successfully applying laser metal deposition with copper in the coal machinery and wind power sectors, marking a notable advancement in the application of laser technologies in these industries. Moreover, ACunity GmbH has been at the forefront of custom-developing automated equipment for its clients, which has been successfully deployed and is now in operation. ACunity GmbH offers comprehensive solutions spanning the entire production chain in high-speed laser metal deposition, laser welding, and additive laser manufacturing. This includes the development of equipment and hardware, process development, and engaging in international research and development collaborations. Serving both domestic and international customers, ACunity GmbH is committed to pushing the boundaries of laser technology applications, ensuring its position as a leader in the field of innovative laser-based manufacturing solutions. ACU’s mission within the LaserWay project is to lead the development and implementation of the EHLA 3D technology for the repair and additive manufacturing of large structural components in the aerospace sector. This involves EHLA to enable precise surface restoration and the efficient generation of near-net-shape structures from metallic materials. As a machine tool builder, ACU is committed to integrating advanced cladding heads, real-time powder mass flow monitoring systems, and tailored material solutions to ensure high-performance outcomes in terms of structural integrity, longevity, and surface quality. The focus remains on achieving both technical excellence and environmental sustainability. ACU’s role entails close collaboration with project partners and domain experts to address the challenges of high-speed, multi-axis laser processing. This includes optimizing laser parameters and process strategies to ensure uniform material deposition, support complex geometries, and expand the capabilities of EHLA beyond traditional coating into full 3D manufacturing and repair. Through this contribution, ACU supports LaserWay’s overarching objective to advance next-generation manufacturing technologies that combine precision, resource efficiency, and industrial scalability. LaserWay

ACunity

Corporate presentation

Role in the Project

Contact